Everything from a single source is not just a motto for us, but is our daily business and has top priority for Schigan. For our customers, we realise the entire value added chain in mechanical and plant engineering, as a professional full-service provider from design, through production to assembly and commissioning. Maintenance and service round off the package accordingly.

Planning / Design

It's important to Schigan to steer project success right from the start.

In mechanical and plant engineering, planning is one of the key success factors and nothing should be left to chance. All the more important is the use of experts. Our planning team brings in comprehensive technical expertise and experience in this first project step, ensuring essential success factors such as an optimal cost structure, ease of maintenance and above all, longevity, during operation.Our offer includes:

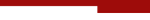

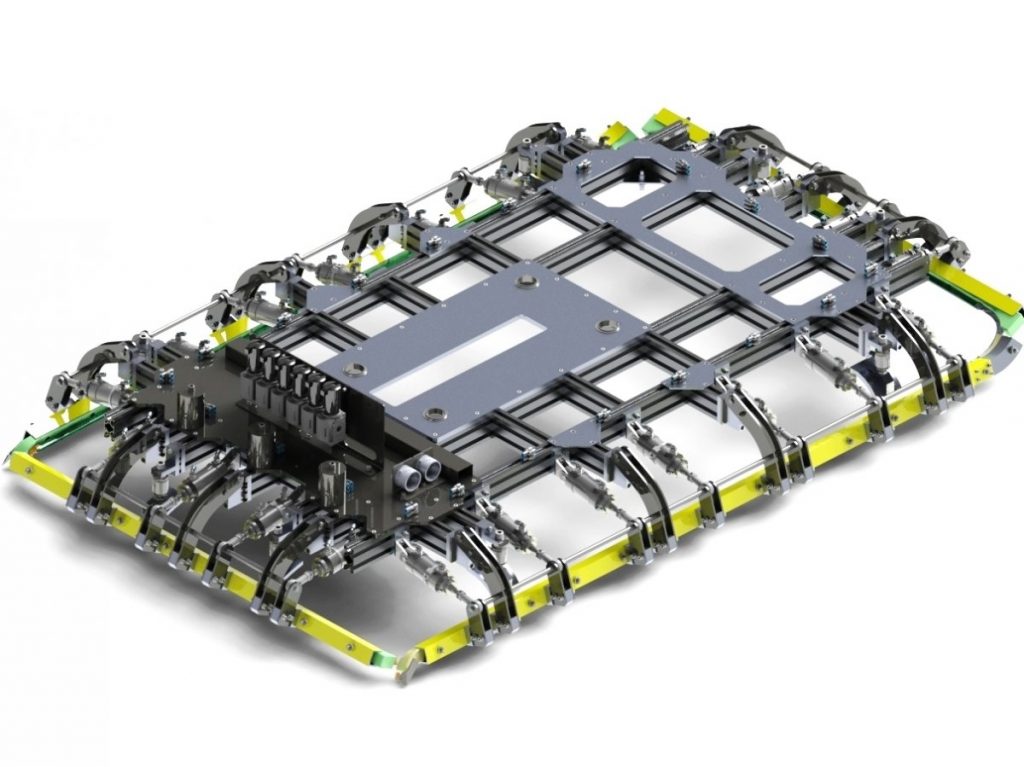

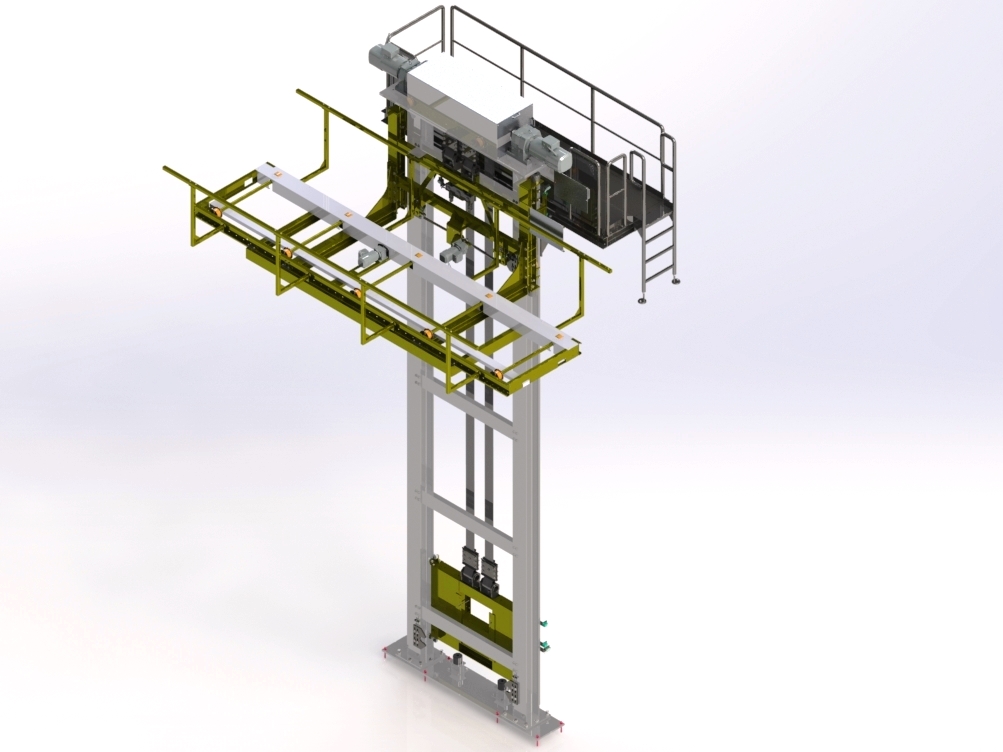

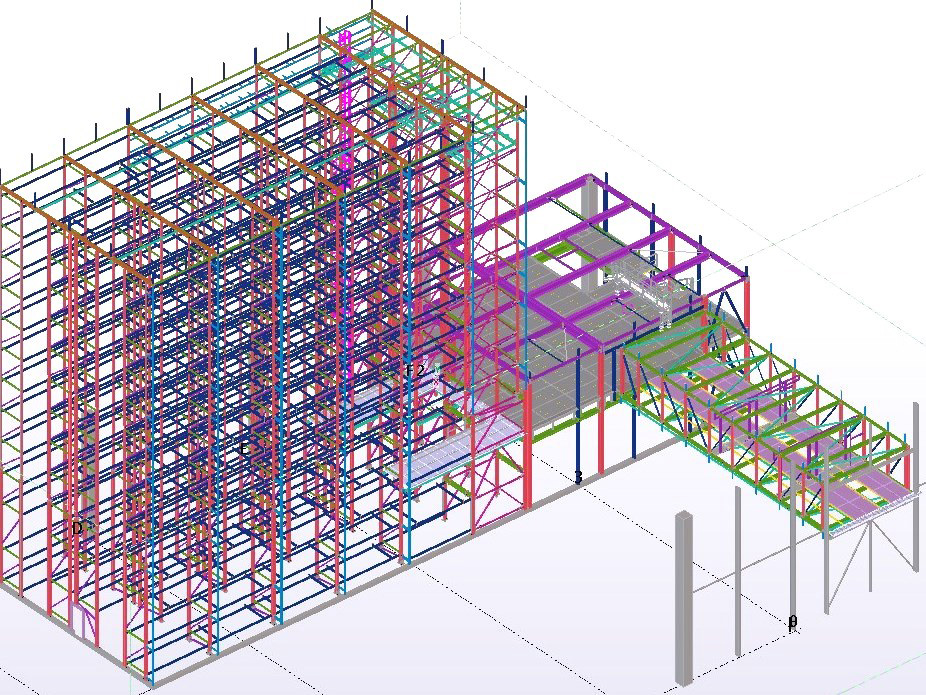

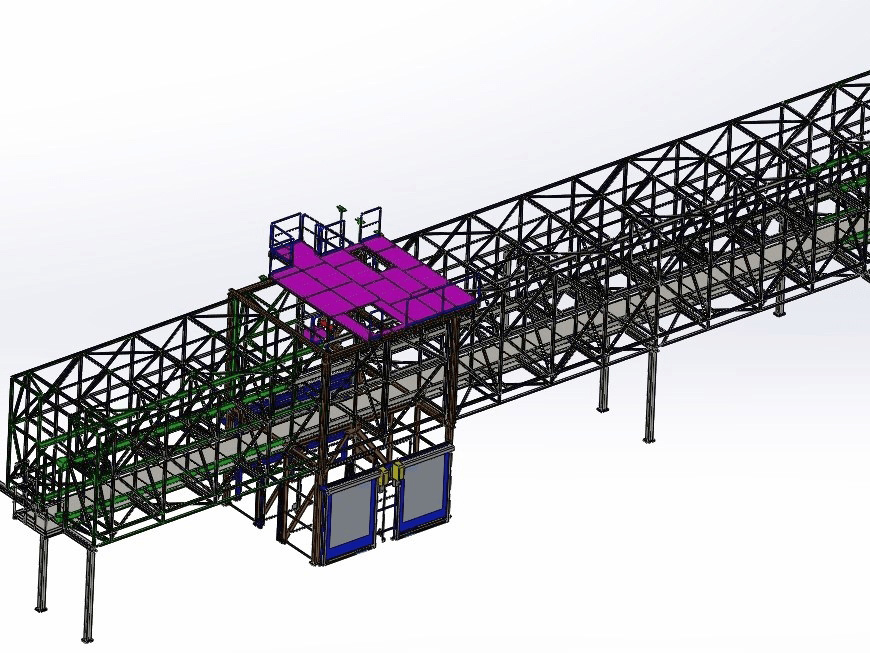

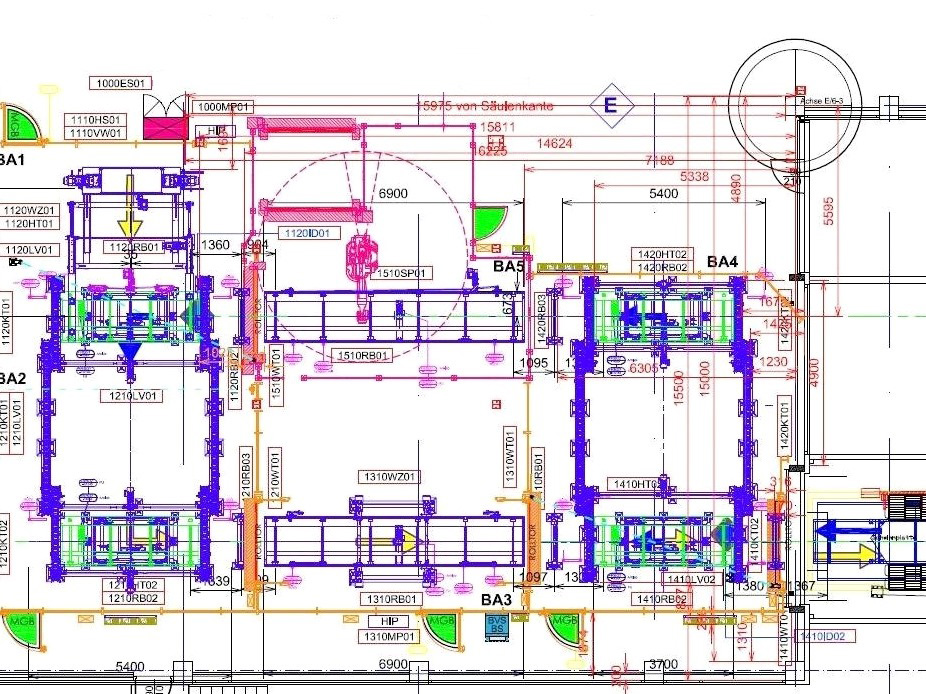

- Preliminary and Concept Planning, Engineering in Catia, Solid Edge, Solid Works, Tekla

- Layout in Autocad, PneumDraw, One Space Designer

- Visualisation for Customer Presentations

- Strength calculation (FEM)

- Optimisation of Existing Designs for Production

Production

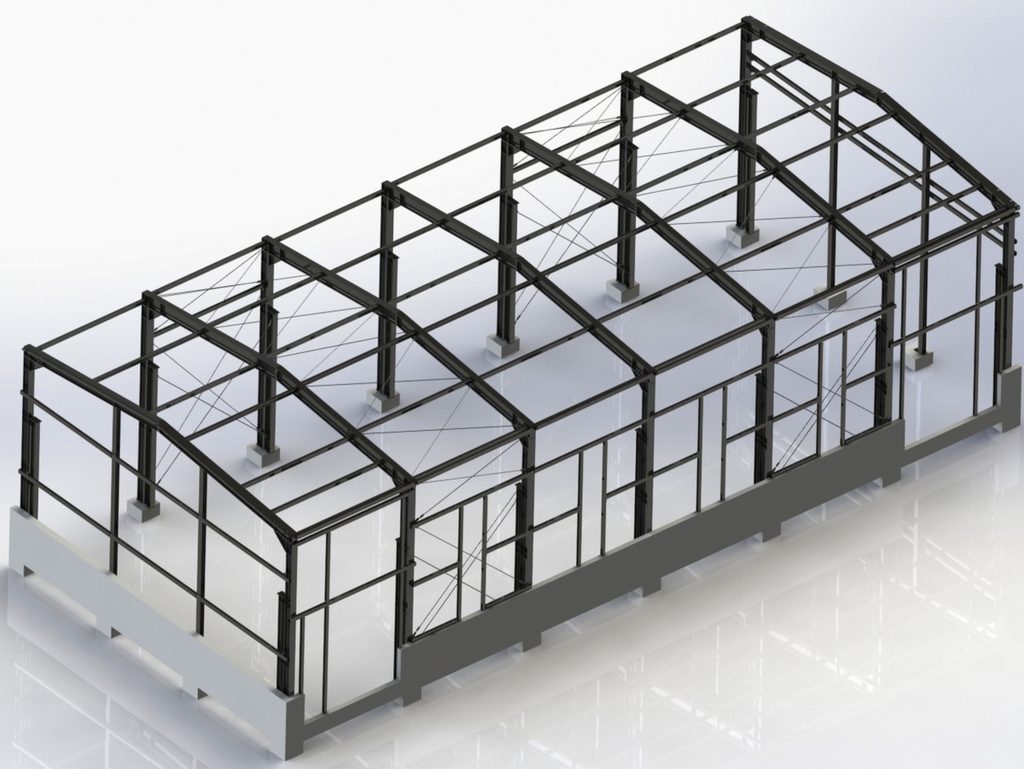

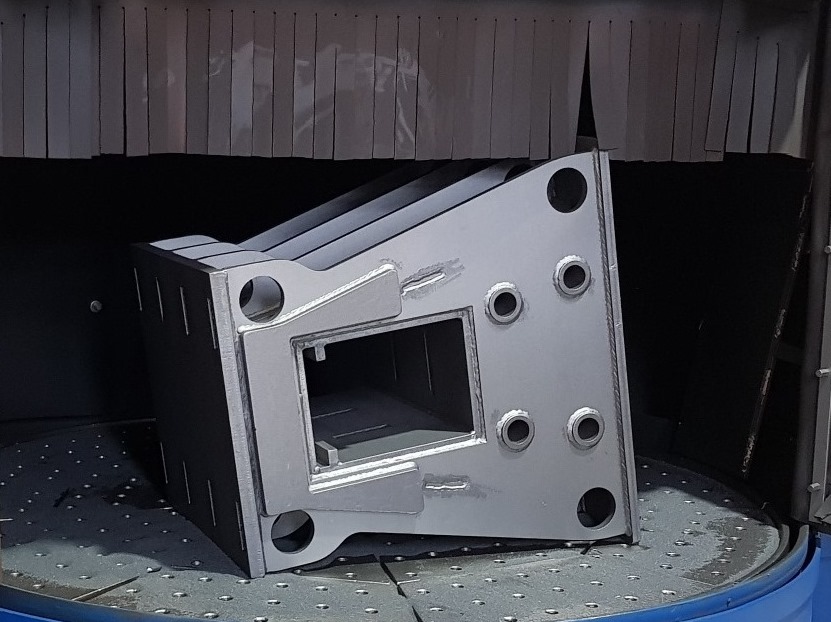

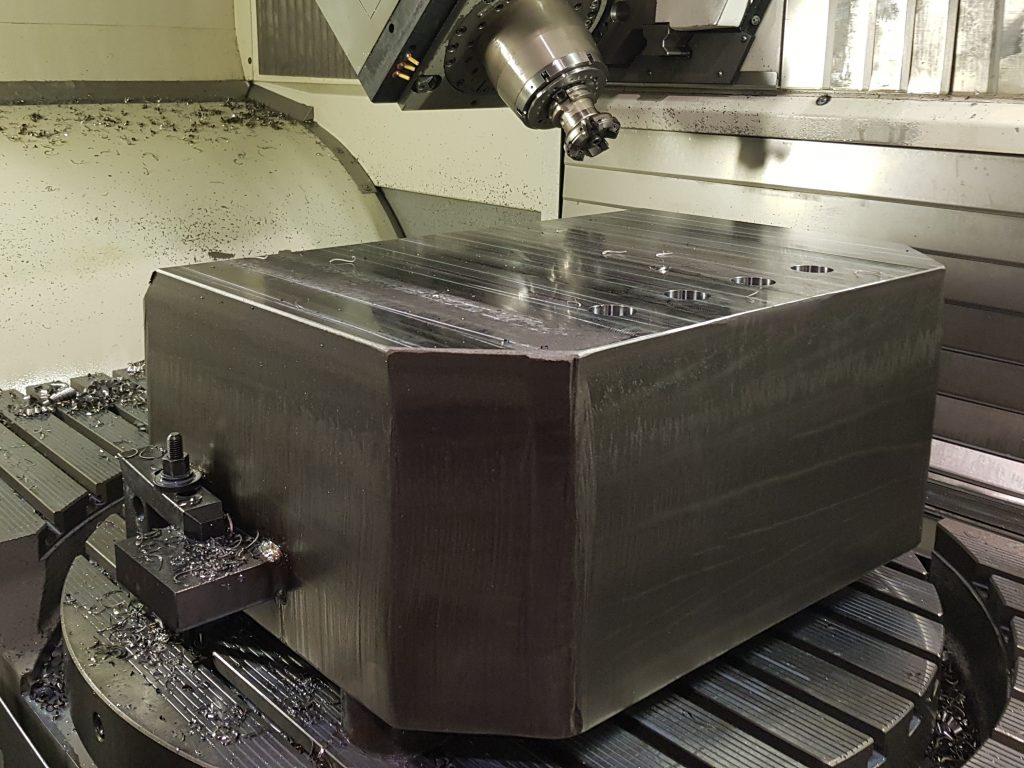

Schigan offers both the possibility of fast, efficient, cost-effective contract manufacturing and production, as well as the special production of individually planned customer systems. A modern machine park on 3,000 m2 of hall space and a state-of-the-art technologies ensure the high-quality processing of steel of all kinds; stainless steel, light metals, cast materials and the like in flexibly configurable milling and turning operations. Small and large parts are manufactured in component sizes up to a total length of 7 meters and up to 16 tons total weight.

Our offer includes:

Mechanical processingMilling: up to a length of 6,000mm

Turning: up to 600mm diameter and a length of 1000mm

Shot blasting: up to 2,200mm diameter and a height of 800mm

Measuring Faro measuring arm: Measuring volume 2,4m - Accuracy: +/- 0,036m

Steel construction and metal fabrication

Steel construction and welding: production capacity of 50 tonnes per week

EN 1090-1 EXC 2 and ISO 3834-3

Certified welders according to EN ISO 9606-1 for structural steel and stainless steel

Welded constructions S235 to 1.4571 to 16 tonnes per piece

Optimum welding quality through pre-heating oven up to 250 °C and component sizes up to a cubature of 3000mm x 2000mm x 800mm

Reliably realised by certified welders and competent skilled workers, including all quality and performance guarantees.